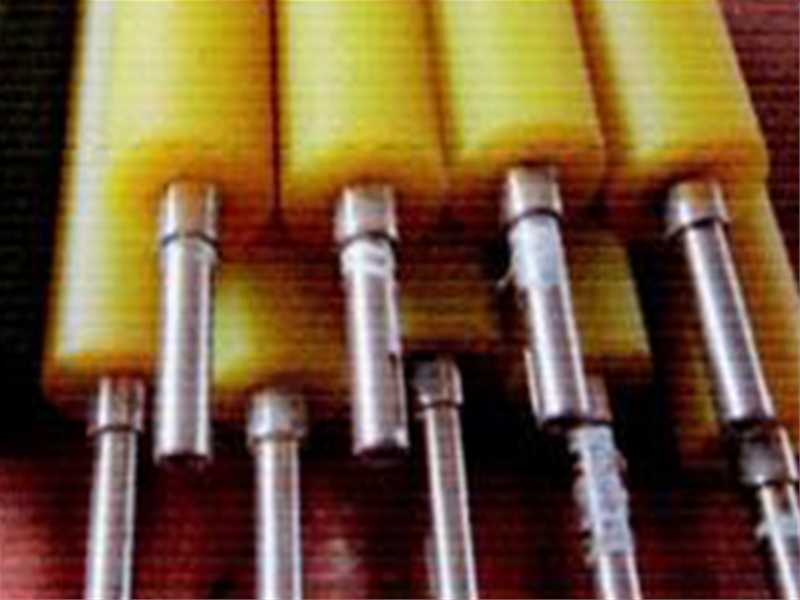

Special silicon rubber for roller (condensation type)

summary

The silicon rubber for roller is a two-component condensation type silicon rubber.

It contains two components AB, A as the main agent and B as the curing agent. The two solutions can be cured at room temperature after mixing, and rapid prototyping can be achieved.

characteristic

1. High resilience, small deformation, high temperature resistance and wear resistance. Long service life.

2. The material is soft and non-toxic.

3. It is not afraid of wet environment and is easy to store.

application

Roller rubber layer.

Product parameters:

|

Condensation type

|

|

hardnss

(ShoreA)

|

Specifications

|

rigid/60

|

neutral/50

|

Softness/45

|

|

model

|

GL-60

|

GL-50

|

GL-45

|

|

Before crosslinking

|

Appearance of base adhesive

|

White or red

|

White or red

|

White or red

|

|

Appearance of crosslinking agent

|

canary yellow

|

canary yellow

|

canary yellow

|

|

Viscosity cps

|

28000±5000

|

28000±5000

|

28000±5000

|

|

operation

|

Cross linking agent addition ratio

|

2~3%

|

2~3%

|

2~3%

|

|

Working time/min

|

60~70

|

60~70

|

60-70

|

|

Complete

curing time/h

|

24

|

24

|

24

|

|

After crosslinking

|

density g/cm3

|

1.33

|

1.33

|

1.33

|

|

hardness/Shore A

|

60±2

|

50±2

|

45±2

|

|

tensile strength/Mpa

|

2.6±0.2

|

2.8±0.2

|

3.2±0.2

|

|

tear strength N/mm

|

2.5±0.5

|

2.5±0.2

|

8±0.2

|

|

Elongation/%

|

80±20

|

80±20

|

150±20

|

|

Linear shrinkage/%

|

≤0.2

|

≤0.2

|

≤0.2

|

Processing program

1. Weigh the required amount of component A and place it in a 3-4 large container. Add component B in proportion according to the product parameter table, fully stir and mix, and then use it after vacuum deaeration

2. The ideal operating environment for this product is 20~25 ℃ and 50% relative humidity. High temperature and high humidity or low temperature and low humidity will affect the gelling time and curing time, so it is necessary to adjust the amount of curing agent to achieve the expected results.

storage

To ensure the good quality of this product, it should be stored in a dry environment with room humidity of 25 ℃ and in a sealed container.

Conventional packaging

Packed in 25kg drums or 200kg drums.